Monobloc

Each model of our pools is manufactured with a monobloc polyester technology, resulting in a complete structure that is absolutely resistant to any possible natural phenomenon, making them the safest on the market.

High quality

We don’t skimp on materials. We use the best polyester resins (also used in the aerospace, nautical and wind energy sectors) reinforced with glass fibre. This guarantees total resistance against chemical agents.

Anti-leaking

Our own heavy-duty nozzle system is a pioneer in the market and ensures, in the unlikely event of a water leak, a quick change from the inside without the need for external work.

Artisanal

We manually carry out the entire process of lamination and reinforcement of the pool, thus achieving the maximum mechanical resistance of the pool and ensuring that each piece is made with the care and dedication it needs.

Installation of a Ceramic de Luxe pool

4 DAYS INSTALLATION TIME

Having the pool of your life at home is easier than you think. Compared to others, the monobloc pool is quick and easy to install. In just a few days you will be ready to enjoy it with your friends and loved ones.

We take care of manufacturing it with great care and attention to detail, in an artisanal way, because we have always done it like that and because we make sure taht you have the perfect pool. Once finished, your official installer takes it to your home and installs it in 4 days, if the characteristics of the work allow it.

Here you can see what the installation of a polyester pool consists of.

The latest in technology and materials

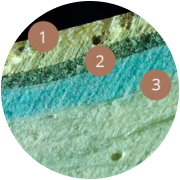

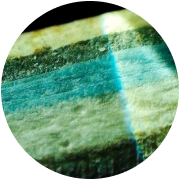

Our production process of pools of the brand Ceramic de Luxe has passed through a very strict laboratory analysis. The previous photograph shows how the gold colour looks.

Microscopic view of the gold colour, in which the 3D effect and the absence of air bubbles can be appreciated.

1. Three layers of three-dimensional gelcoat. 2. High-resistance chemical barrier. 3. Sandwich laminate with structural interlaced mat.

Plate after long ageing process in laboratory.

Ceramic de Luxe guarantee

The best guarantee in the market

Our goal is full satisfaction during your times of relaxation. That’s why we at Ceramic de Luxe offer top-quality products, with the best guarantees in the market.

-

10 years gel coat guarantee -

20 years osmotic acid guarantee -

40 years structure guarantee

Request budget

Enjoy the pool of your dreams.

Discover our offers in polyester pools and get ready to upgrade your garden to its best version.

We serve almost all of Western Europe!